Report reveals ‘True Impact’ of manufacturing is nearly a quarter of UK GDP

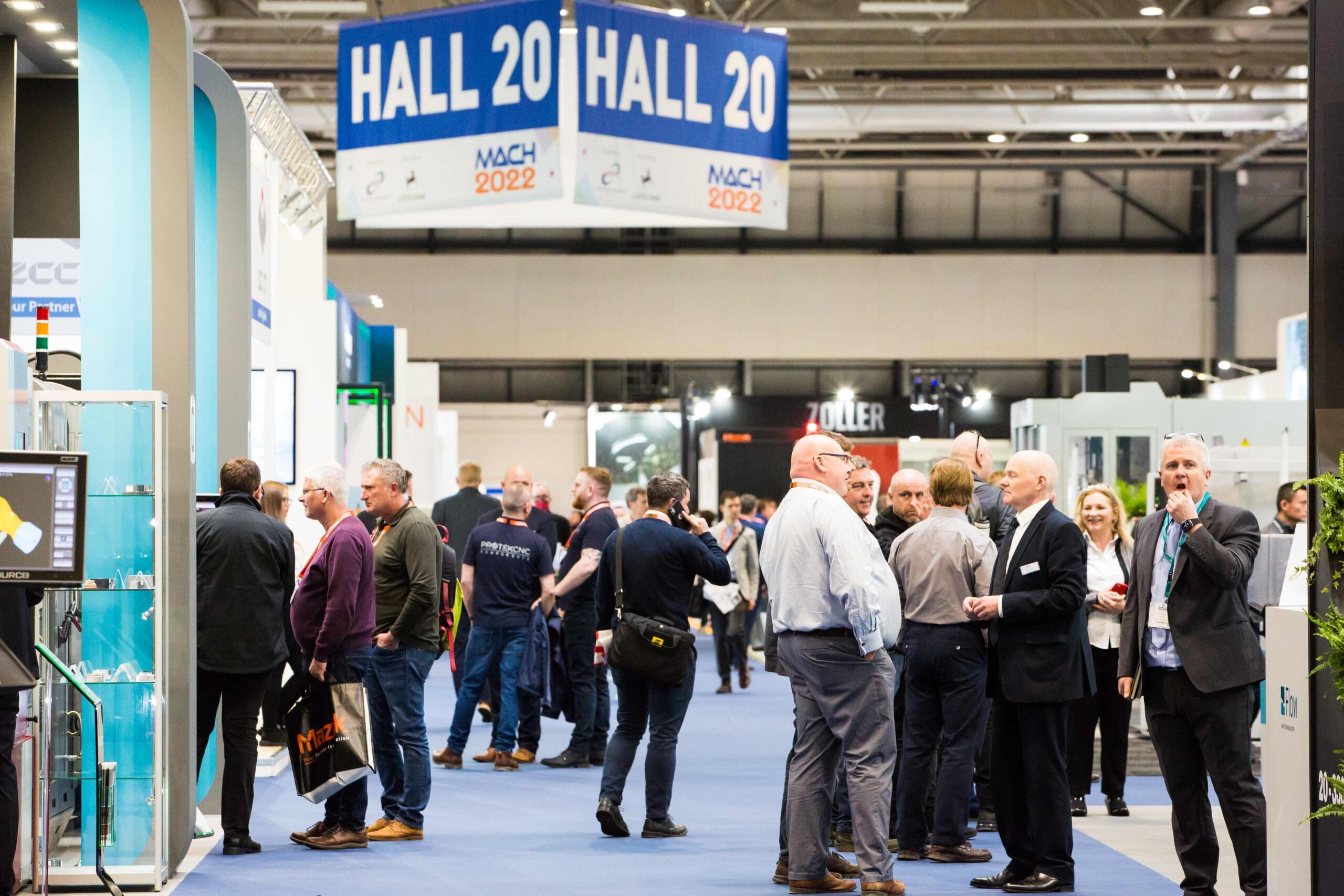

/Manufacturing is having a far greater impact on the UK economy than first thought according to a major new report released today. ‘The True Impact of UK Manufacturing’, which will be unveiled at MACH 2024 in Birmingham later, shows industry is worth £518billion and supports 7.3million UK jobs directly and across the supply chains/communities it […]

Read more

Visit the MMMA Metalworking Village in Hall 6 at MACH 2024

/Established in 1949, the Metalforming Machinery Makers Association (MMMA) is the only trade body solely dedicated to the sheet metalforming industry representing companies specialising in sheet metal, metalforming and fabrication. MMMA will be celebrating its 75th Anniversary at MACH 2024 which takes place between 15-19 April at the NEC Birmingham. MMMA is very excited to […]

Read more

Walking the floor: A starting point for sustainability

/New for MACH 2024, Lloyds Bank is hosting a Sustainability Solutions Hub at Stand 18-650 in partnership with the Manufacturing Technology Centre (MTC). For manufacturers looking to understand where to begin on their journey to Net Zero or what support is available, we are on hand to help. Here, David Atkinson, UK Head of Manufacturing […]

Read more

New Knowledge Hubs initiative at MACH 2024

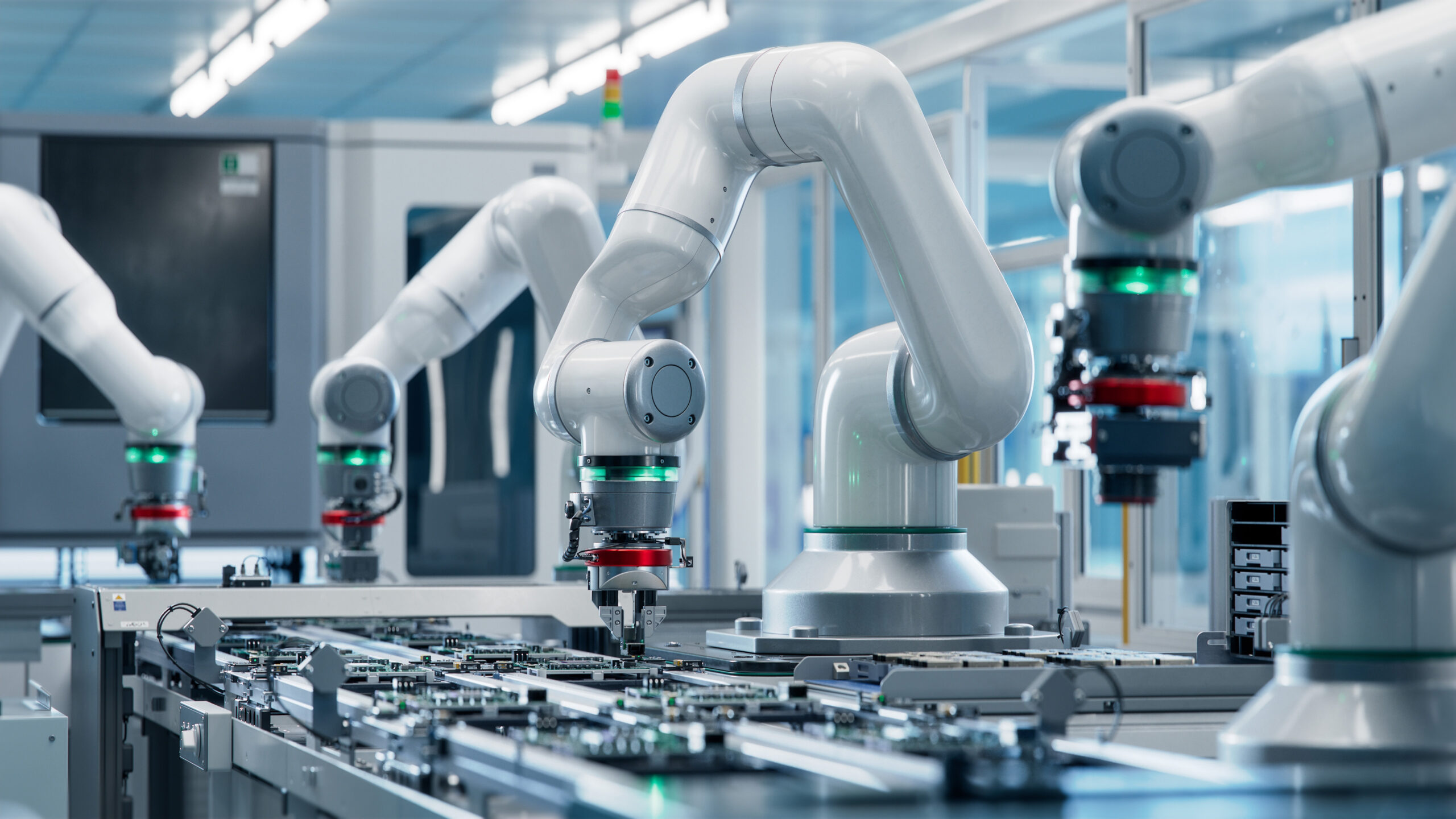

/Reversing UK manufacturing’s poor record for adopting new technology will be tackled head on at MACH 2024 as The Manufacturing Technologies Association (MTA) launches its new Knowledge Hubs initiative, showcasing how to adopt new technology to improve productivity and efficiency in manufacturing.

Read more

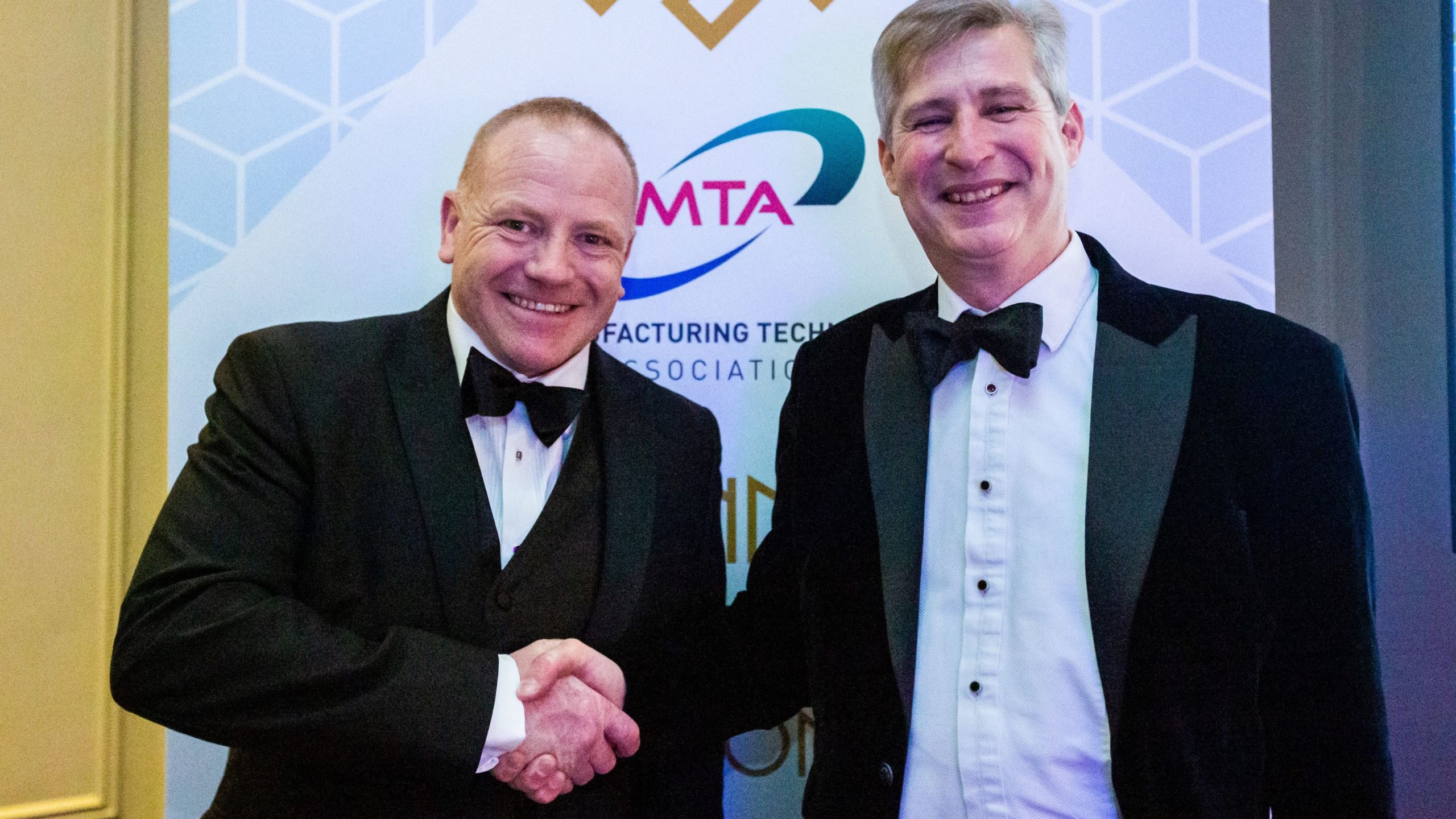

Changing times: Manufacturers’ unprecedented opportunity

/We’re looking forward to meeting manufacturers from across the country at MACH 2024, to hear about their strategies for the year ahead and discuss how we can support.

Here David Atkinson, UK Head of Manufacturing SME & Mid Corporates, Lloyds Bank, and James Selka, CEO of Manufacturing Technologies Association (MTA) discuss their ambitions for the sector in 2024.

Sandvik Coromant announced as headline sponsor of the MACH 2024 Education & Development Zone

/The Education and Development (E&D) Zone at MACH 2024 is once again being sponsored by global metalcutting specialist, Sandvik Coromant.

Read more

Knowledge Hub initiative to be core theme of MACH 2024

/Reversing UK manufacturing’s poor record for adopting new technology will be tackled head on at MACH 2024. The Manufacturing Technologies Association (MTA) has made it its mission to spearhead growth by using its flagship event to launch its new Knowledge Hubs initiative. The programme showcases the latest technology to exhibitors, helping manufacturers learn more about […]

Read more

MTA announces flagship initiative to help UK manufacturers adopt latest technologies

/The Manufacturing Technologies Association (MTA) will use its flagship event, MACH 2024, to launch its new initiative to help UK manufacturers become more competitive while improving efficiency and sustainability. A series of Knowledge Hubs will feature at the exhibition, taking place at the NEC, Birmingham from 15-19 April 2024, all designed to encourage UK engineering-based […]

Read more

Manufacturers pledge support for MACH 2024 with more than 80% of exhibition space sold

/The UK’s engineering-based manufacturing sector has once again backed the industry’s largest trade show, booking more than 80% of floorspace at MACH 2024 with more than 200 days still to go before doors open at the NEC in Birmingham. Show organiser, the Manufacturing Technologies Association (MTA) said it was delighted with the response but stressed […]

Read more

Lloyds Bank confirmed as headline sponsor of MACH 2024

/The countdown to MACH 2024, the UK’s national event for inspiring, innovating and connecting manufacturing, has reached an important landmark, with just one year to go before the doors to the National Exhibition Centre in Birmingham open for the UK’s national event for engineering-based manufacturing. In recognition of the landmark – and reaffirming their commitment […]

Read more

£multi-million machining deal

/DTS (UK) and Nicolas Correa have strengthened their long-term relationship with WEC Group Ltd in a £multi-million deal at MACH 2024 this week. The Darwen-based manufacturer is building its factory of the future and is looking to become the largest sub-contract machining shop in Europe. To achieve this aim it has used the show to […]

Read more

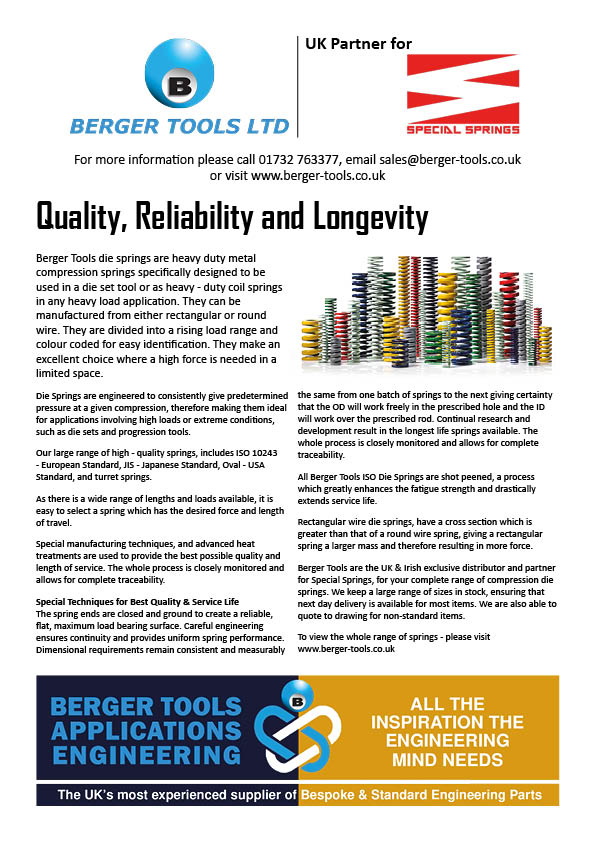

Quality, Reliability and Longevity

Please open the “Featured Image” file below. For further information please call Berger Tools on 01732 763377, email [email protected] or visit www.berger-tools.co.uk Berger Tools -Applications Engineering. From the UK’s most experienced supplier of Bespoke & Standard Engineering Parts.

Read more

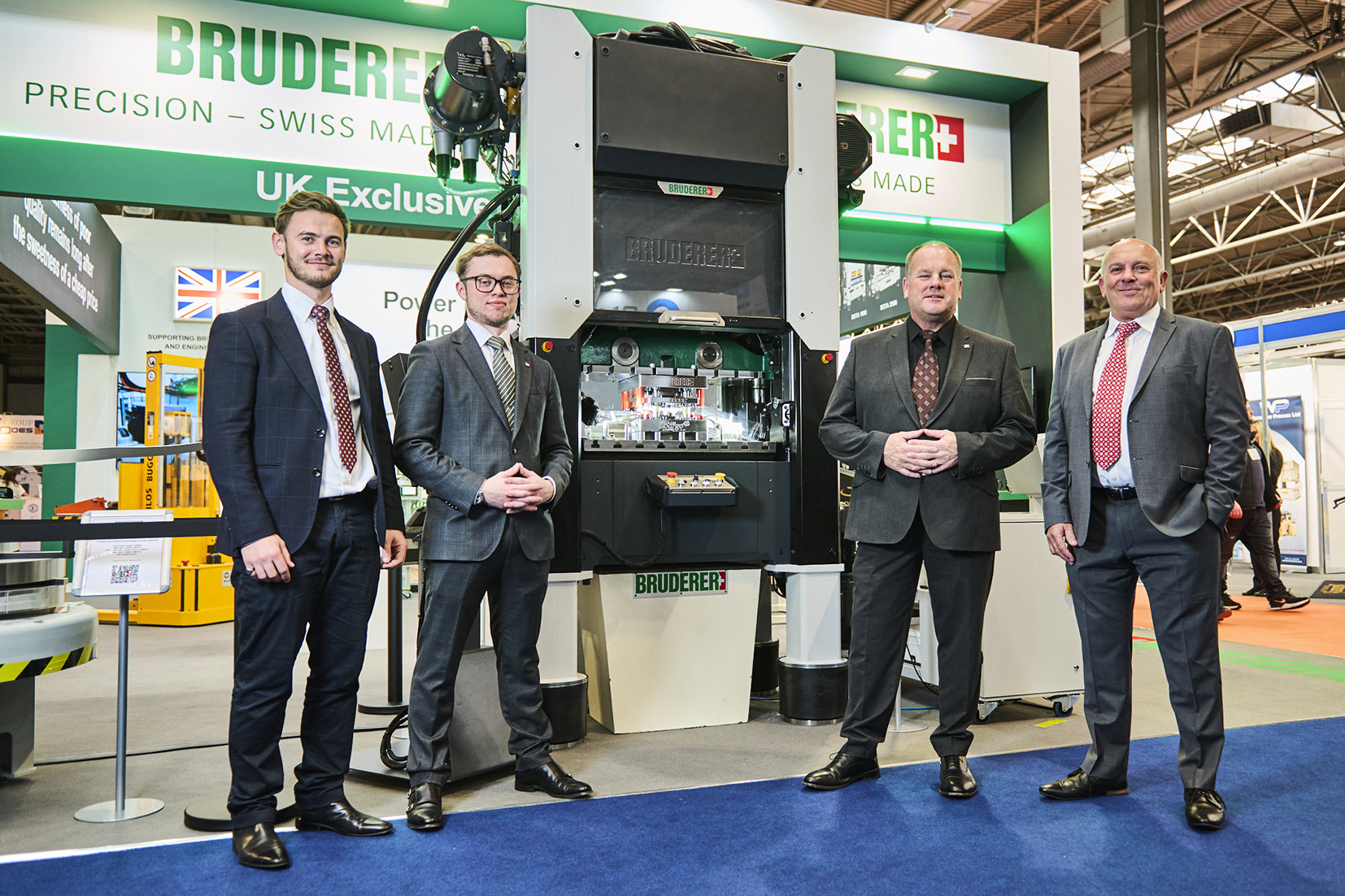

Match made in tooling leads to press investment at MACH 2024

A specialist supplier to F1, automotive and aerospace sectors is looking to increase its tool try-out capacity by purchasing its first Bruderer press at MACH 2024. Alan Spargo Ltd, which celebrates 50 years in business in 2025, has invested in a BSTA 40-tonne machine to help it provide its growing list of customers with the […]

Read more

Giving Clean a New Meaning

Please open the “Featured Image” file below. For further information please call Berger Tools on 01732 763377, email [email protected] or visit www.berger-tools.co.uk Berger Tools -Applications Engineering. From the UK’s most experienced supplier of Bespoke & Standard Engineering Parts.

Read more

Cleaning-Optimized Leveling Feet

Please open the “Featured Image” file below. For further information please call Berger Tools on 01732 763377, email [email protected] or visit www.berger-tools.co.uk Berger Tools -Applications Engineering. From the UK’s most experienced supplier of Bespoke & Standard Engineering Parts.

Read more

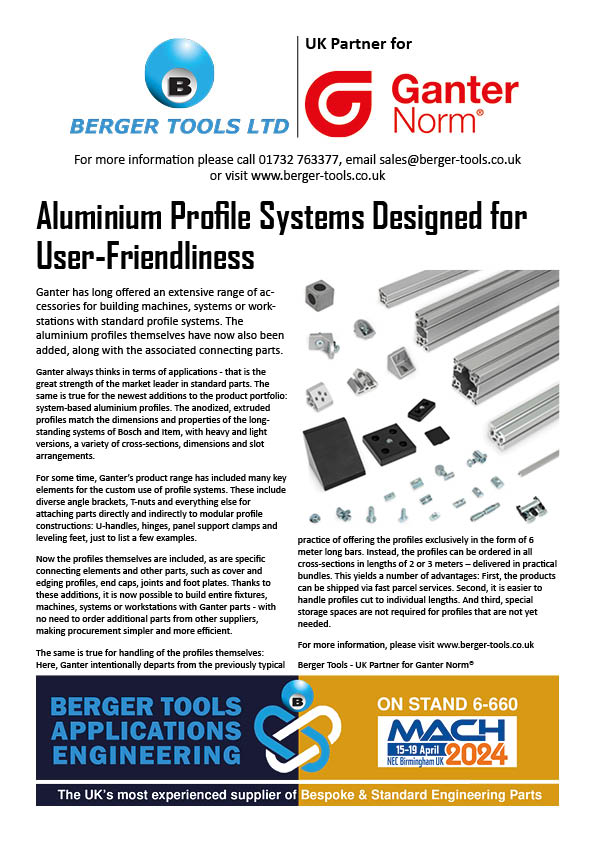

Aluminium Profile Systems Designed for User-Friendliness

Please open the “Featured Image” file below. For further information please call Berger Tools on 01732 763377, email [email protected] or visit www.berger-tools.co.uk Berger Tools -Applications Engineering. From the UK’s most experienced supplier of Bespoke & Standard Engineering Parts.

Read more

Green Machining Solutions – Vegetable Based Oils For a More Sustainable and Safer Future!

M-O-8 Specialities Ltd, a company at the forefront of sustainable practices, have been supplying its Green Machining Range of advanced cutting oils and lubricants for over 15 years. As the global focus on sustainability and safety in business operations intensifies, the transition away from petroleum-based mineral oil in manufacturing processes is gaining significant importance. Conventional […]

Read more

The Impressive EMG Press Range

Please open the “Featured Image” file below. For further information please call Berger Tools on 01732 763377, email [email protected] or visit www.berger-tools.co.uk Berger Tools -Applications Engineering. From the UK’s most experienced supplier of Bespoke & Standard Engineering Parts.

Read more

Applied Concepts to Showcase Innovative Blasting Solutions at MACH 2024

Applied Concepts, a leading manufacturer of high-quality blasting machines, announces its participation in MACH 2024, the premier event for engineering and manufacturing professionals alongside Engenuity Midlands Engineering. Held at NEC Birmingham from 15-19 April 2024, MACH 2024 provides a platform for industry leaders to showcase the latest innovations and technologies. Find Applied Concepts and Engenuity […]

Read more

Cooney Precision Ltd to Showcase Precision Engineering Expertise at MACH 2024 with Engenuity Engineering Cluster

Cooney Precision Ltd, a leading provider of precision machining services, proudly announces its participation in MACH 2024 alongside the Engenuity Engineering Network. The event, scheduled for 15-19 April 2024, will be held at NEC Birmingham and will bring together industry leaders, innovators and enthusiasts to explore the latest advancements in engineering and manufacturing. Find […]

Read more