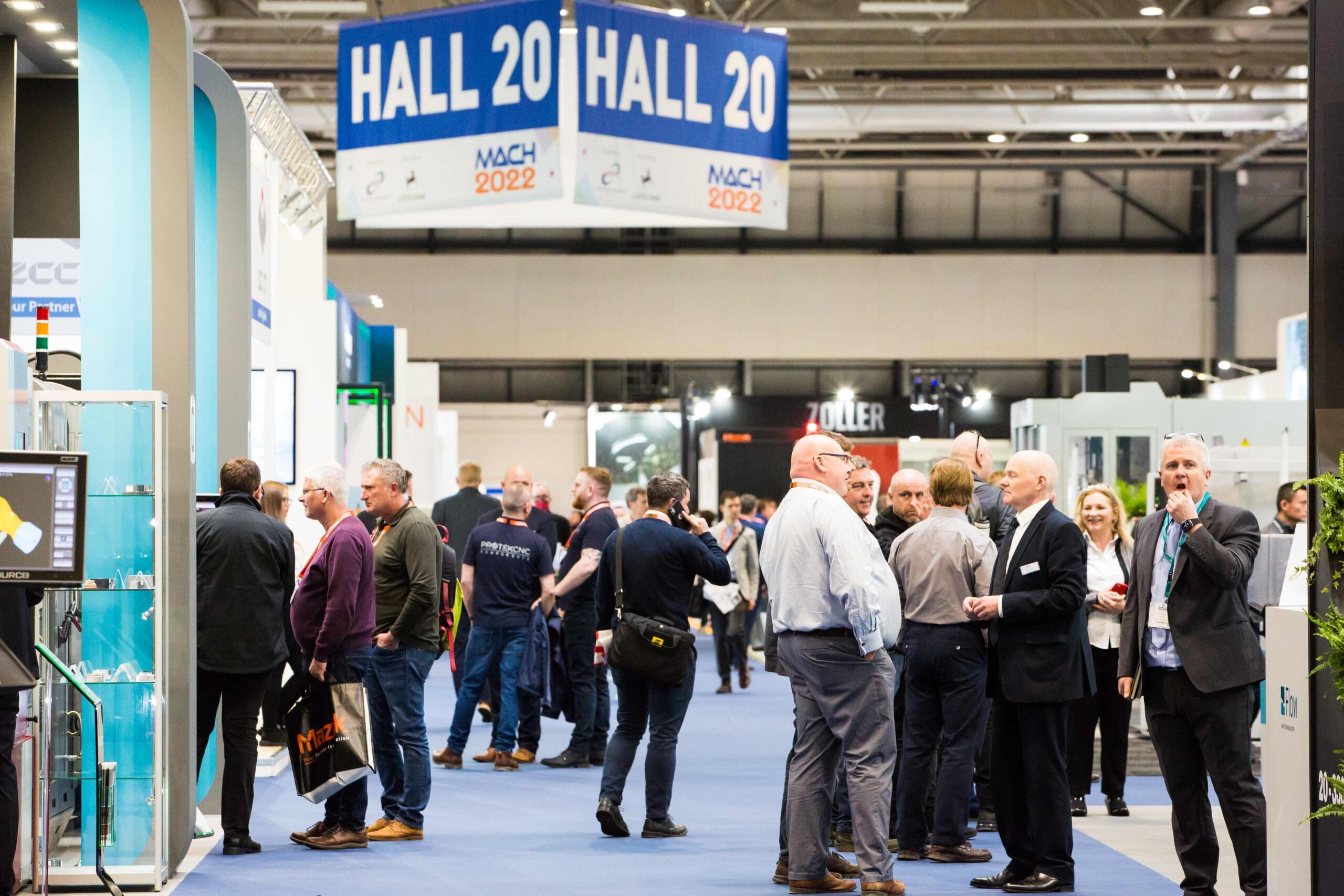

MACH 2024 is hailed a roaring success

/MACH 2024, the UK’s national event for inspiring, innovating, and connecting manufacturing, has once again been hailed as a triumph, with thousands of visitors filling the five halls at the NEC in Birmingham over the weeklong show in April. The 2024 edition of the exhibition saw a 6% increase in the number of visitors meaning […]

Read more

Report reveals ‘True Impact’ of manufacturing is nearly a quarter of UK GDP

/Manufacturing is having a far greater impact on the UK economy than first thought according to a major new report released today. ‘The True Impact of UK Manufacturing’, which will be unveiled at MACH 2024 in Birmingham later, shows industry is worth £518billion and supports 7.3million UK jobs directly and across the supply chains/communities it […]

Read more

Visit the MMMA Metalworking Village in Hall 6 at MACH 2024

/Established in 1949, the Metalforming Machinery Makers Association (MMMA) is the only trade body solely dedicated to the sheet metalforming industry representing companies specialising in sheet metal, metalforming and fabrication. MMMA will be celebrating its 75th Anniversary at MACH 2024 which takes place between 15-19 April at the NEC Birmingham. MMMA is very excited to […]

Read more

Walking the floor: A starting point for sustainability

/New for MACH 2024, Lloyds Bank is hosting a Sustainability Solutions Hub at Stand 18-650 in partnership with the Manufacturing Technology Centre (MTC). For manufacturers looking to understand where to begin on their journey to Net Zero or what support is available, we are on hand to help. Here, David Atkinson, UK Head of Manufacturing […]

Read more

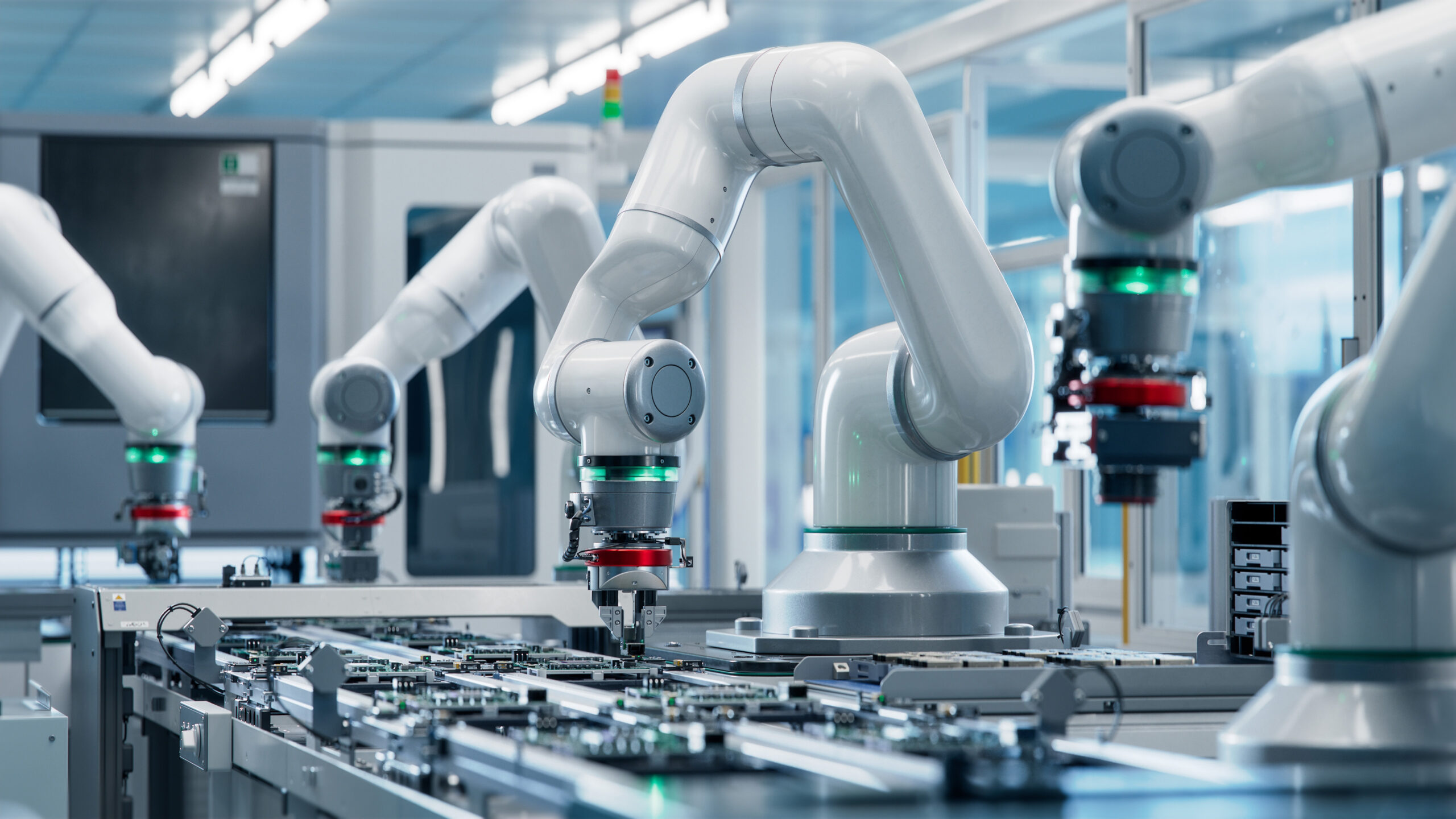

New Knowledge Hubs initiative at MACH 2024

/Reversing UK manufacturing’s poor record for adopting new technology will be tackled head on at MACH 2024 as The Manufacturing Technologies Association (MTA) launches its new Knowledge Hubs initiative, showcasing how to adopt new technology to improve productivity and efficiency in manufacturing.

Read more

Changing times: Manufacturers’ unprecedented opportunity

/We’re looking forward to meeting manufacturers from across the country at MACH 2024, to hear about their strategies for the year ahead and discuss how we can support.

Here David Atkinson, UK Head of Manufacturing SME & Mid Corporates, Lloyds Bank, and James Selka, CEO of Manufacturing Technologies Association (MTA) discuss their ambitions for the sector in 2024.

Sandvik Coromant announced as headline sponsor of the MACH 2024 Education & Development Zone

/The Education and Development (E&D) Zone at MACH 2024 is once again being sponsored by global metalcutting specialist, Sandvik Coromant.

Read more

Knowledge Hub initiative to be core theme of MACH 2024

/Reversing UK manufacturing’s poor record for adopting new technology will be tackled head on at MACH 2024. The Manufacturing Technologies Association (MTA) has made it its mission to spearhead growth by using its flagship event to launch its new Knowledge Hubs initiative. The programme showcases the latest technology to exhibitors, helping manufacturers learn more about […]

Read more

MTA announces flagship initiative to help UK manufacturers adopt latest technologies

/The Manufacturing Technologies Association (MTA) will use its flagship event, MACH 2024, to launch its new initiative to help UK manufacturers become more competitive while improving efficiency and sustainability. A series of Knowledge Hubs will feature at the exhibition, taking place at the NEC, Birmingham from 15-19 April 2024, all designed to encourage UK engineering-based […]

Read more

Manufacturers pledge support for MACH 2024 with more than 80% of exhibition space sold

/The UK’s engineering-based manufacturing sector has once again backed the industry’s largest trade show, booking more than 80% of floorspace at MACH 2024 with more than 200 days still to go before doors open at the NEC in Birmingham. Show organiser, the Manufacturing Technologies Association (MTA) said it was delighted with the response but stressed […]

Read more

Tebis Present CAD/CAM/MES Intelligent Manufacturing at MACH 2024

Tebis, a specialist provider of CAD/CAM and MES solutions which offers world leading advanced intelligent manufacturing technologies for CNC machining process optimisation, standardisation and CAM automation, will be exhibiting at MACH 2024. The event is to be held at NEC in Birmingham from Monday the 15th until Friday the 19th of April 2024. Tebis will […]

Read more

Swarf compactor, power packs for machine tools

Yuken Europe: Leading the Charge in Hydraulic Engineering for a Sustainable Future In the fast-paced world of manufacturing, staying at the forefront of hydraulic engineering is essential. Yuken Europe, part of the global Yuken group with a legacy dating back to 1929, is set to make a significant impact at the MACH Exhibition 2024, held at […]

Read more

Swing VII 3kw 3015 Penta Fiber laser, featuring IPG laser source and Precitec cutting head technology for Vantage Products Ltd

Penta Laser UK –VANTAGE-July 2023 Improving efficiencies at Vantage Products Limited Market leading manufacturer and distributor of fabricated stainless steel healthcare and sanitary ware items, Vantage Products Ltd of Daventry (www.vantageproducts.co.uk) have recently taken delivery of a brand new 3kw fiber laser cutting system from Penta Laser UK. The system supplied by Penta Laser UK […]

Read more

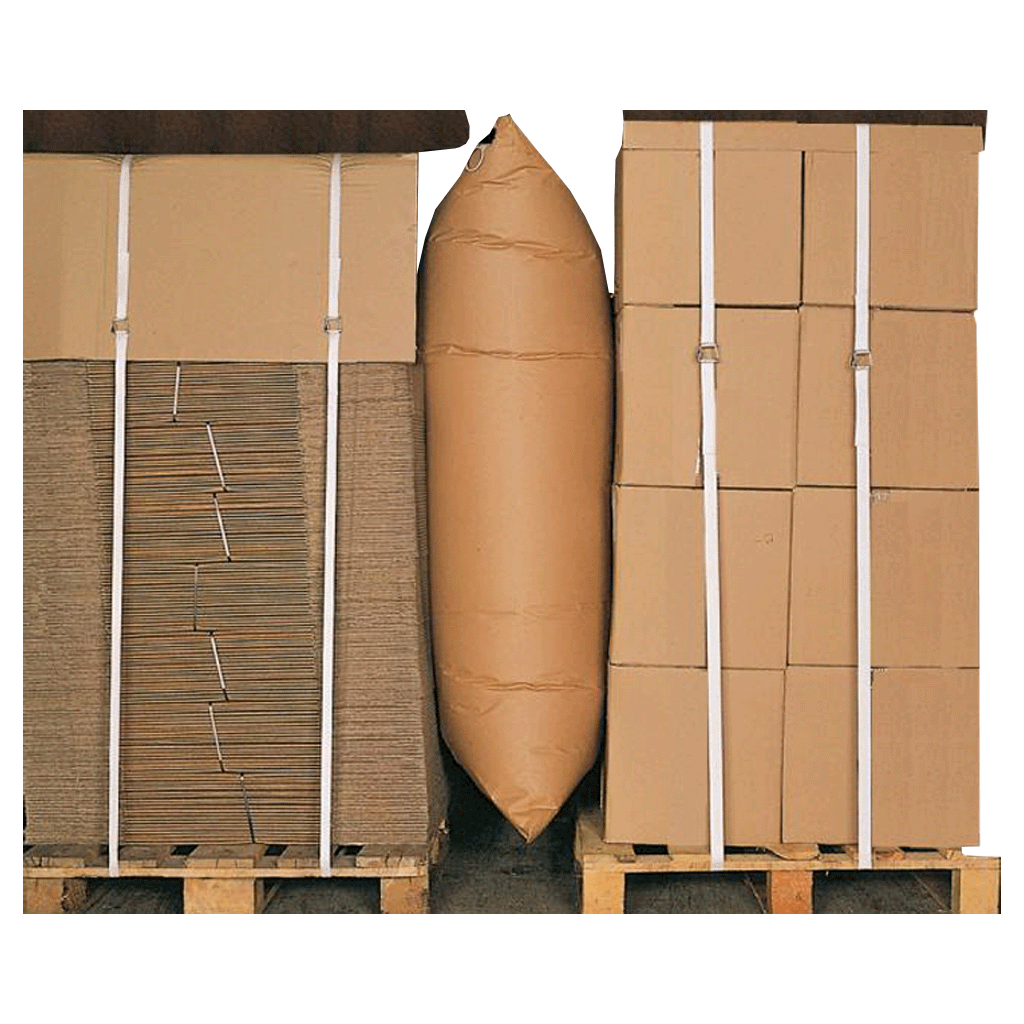

Allpack Unveils Innovative Dunnage Bag Solutions with the Launch of Contain-A-Pac Brand

Contain-A-Pac is Allpack’s new brand of Dunnage Bags designed to revolutionise the shipping and logistics industry, was launched in Q4 last year, to enhance its cargo protection product range. Dunnage Bags, an essential component in securing cargo during transportation, play a crucial role in preventing damage and ensuring the safe delivery of goods. The Contain-A-Pac […]

Read more

Allpack Achieves Carbon-Neutral Britain Status, Demonstrating Commitment to Sustainability

Allpack, a leading packaging company, proudly announces its achievement of securing Carbon Neutral Britain certification, marking a significant milestone in the company’s ongoing commitment to environmental sustainability. In an era where businesses increasingly recognise the importance of reducing their carbon footprint, Allpack has taken proactive steps to address climate change and contribute to a greener […]

Read more

Allpack Launches PaintGuard™️: The Sustainable Packaging In-Transit Solution for Liquid Products

Allpack, a leader in sustainable packaging solutions, is proud to announce the launch of its revolutionary new product, PaintGuard™️. PaintGuard™️ is a sustainable packaging in-transit solution for liquid products providing unmatched protection for paint and other liquid products against damage during transportation. PaintGuard™️ is designed to be environmentally friendly, made of 100% recycled materials, and […]

Read more

PNJ Laser Cutting upgrade operations with expanded MSS Nitrocube system.

Laser cutting specialists and manufacturers of Gearmate bespoke vehicle storage systems – PNJ Laser Cutting in Alcester – have recently expanded their laser cutting operations to meet increased production demands. As part of this expansion, PNJ have also upgraded their on-site nitrogen generation equipment by adding a second MSS Nitrocube with additional high pressure nitrogen […]

Read more

ZAYER 6-axis multi-tasking machine set to stun MACH 2024

Large ZAYER 6-axis multi-tasking machine set to stun MACH 2024 visitors with its size, power, speed and versatility. A large-capacity ZAYER machine tool is one of the biggest machines Mills CNC has ever showcased at a MACH Show. Company is confident that the ZAYER XIOS G MT, a 6-axis multi-tasking machine with integrated […]

Read more

Biogas boosts green credentials with on-site nitrogen generation from MSS

Innovative Renewable Energy Technology specialists, Biogas Products Ltd in Dudley have recently added a new MSS Nitrocube high pressure nitrogen generation system to their laser cutting operation. Having used bundled gas cylinders to supply their fibre laser previously, Biogas decided that they would benefit from the flexibility and convenience of a Nitrocube system. Tony Smith, […]

Read more

Benchdogs steps up with high pressure laser gas from MSS Nitrogen

Innovative MFT tooling manufacturer, Benchdogs Ltd in Taunton, Somerset have recently added a new MSS Nitrocube high pressure nitrogen generation system to their laser cutting operation. Having used bundled gas cylinders to supply their fibre laser for several years, Benchdogs decided that they needed to improve the reliability and reduce costs for their high-pressure nitrogen […]

Read more