Pressure Swing Adsorption (PSA) technology is used with specially developed adsorbents called Carbon Molecular Sieve (CMS) to separate nitrogen from air to be able to use pure nitrogen in many applications.

First, air is compressed up to 10 bars with the help of compressors, then air is dried out to remove the moisture in the air either using refrigerant dryers or desiccant dryers. Filtration takes place thereafter to filter out the remaining particles, aerosol and oil which is in the pressurized air stream. Carbon Tower ensures long term oil free nitrogen delivery.

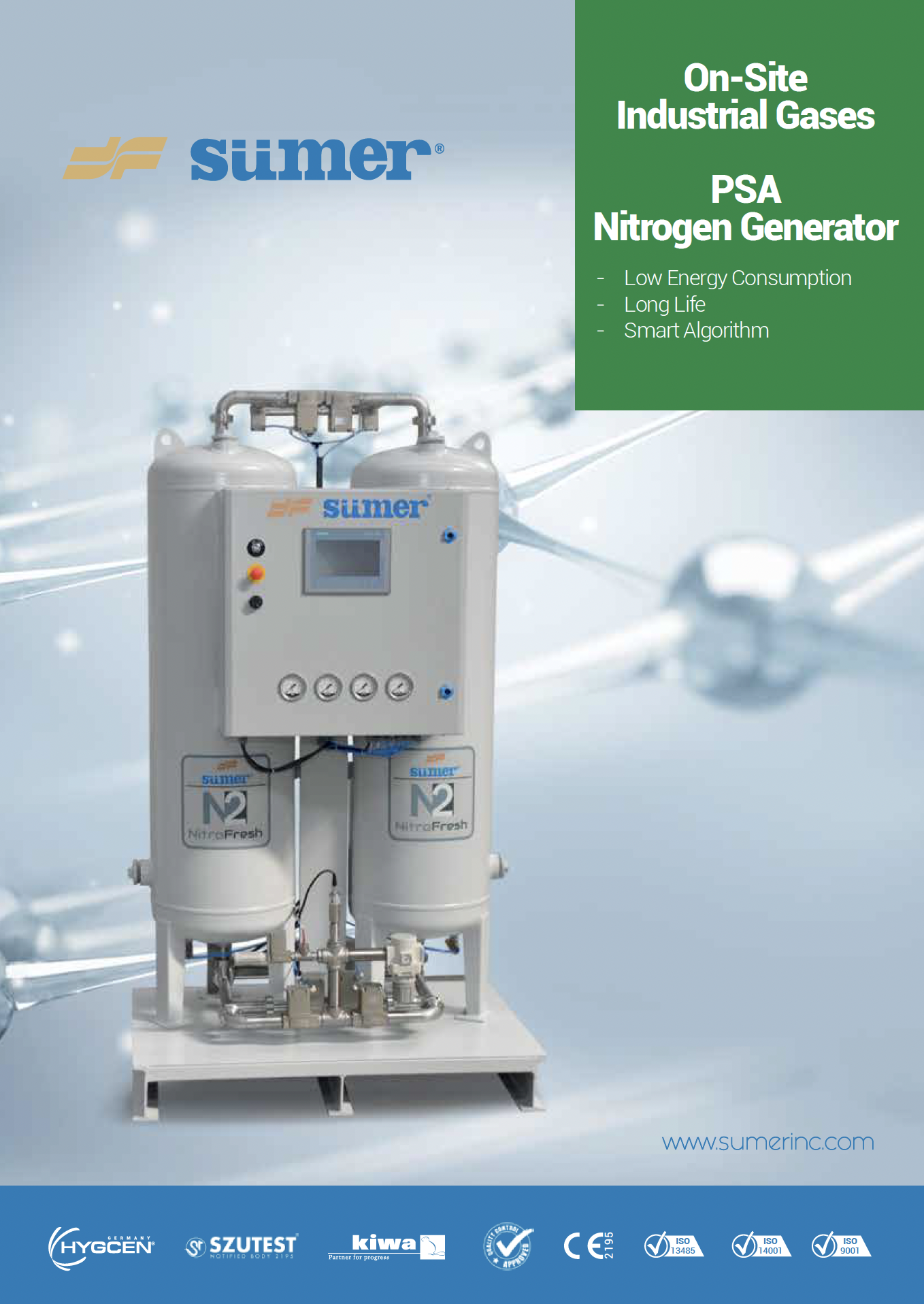

PSA unit consists two tanks filled with CMS. Each column undergoes cyclic sequence of pressurization, generation, equalization and exhaust cycles for continuous flow of high purity nitrogen.

Reduction of nitrogen cost

Safe low-pressure nitrogen usage instead of high-pressure cryogenic cylinders

Elimination of logistical and administrative operations

Elimination of orders and deliveries

Ready to use high technology solutions

Nitrogen is the world’s safety blanket. With the application list continuing to grow, coupled with advances in manufacturing, on-site nitrogen is more accessible than ever to customers of all sizes. With purities ranging from 95%-99.999%, you can easily evaluate your operational cost based on purity produced, estimated maintenance and electrical kW costs.

Laser cutting

Food & beverage (storage and packaging)

Pharmaceutical applications

Plastic injection molding

Electronics

Semiconductor manufacturing

Chemical applications

Metal heat treatment

Cable and optical fiber industries Glass industries

Fire prevention

Aquaculture

Whether your company is specialized in laser cutting, chemical manufacturing, electronics or food and beverage, a trustable supply of industrial nitrogen is crucial. Compared to the on-demand delivery of gas bottles or tanks, on-site production of nitrogen offers many advantages such as cost savings and continuous availability.

SUMER’s advanced nitrogen generators offer you the on-site production of nitrogen at the lowest possible cost.

Nitrogen from 95% to 99.999% Fully Automatic 24/7

Real time trends of process parameters

Visual recommended service maintenance reminders

Algorithm against electricity cuts-off (Purity does not drop after electricity cuts-off)

![]() Smart Algorithm (Generator automatically adjusts its purity regarding nitrogen flow)

Smart Algorithm (Generator automatically adjusts its purity regarding nitrogen flow)

Highest packing density of CMS (specifically designed filling station)

Uniform flow distribution design to maximize CMS life

Humid protection system (Humid air cannot enter the CMS tanks)

Industrial Grade Air and Nitrogen Filtration

High Efficiency CMS

Real Time Monitoring

Remotely Manageable via Ethernet

Recording Capabilities and Data Logging

Multi-level secured access for supervisory control

Top quality SMC and OMAL valves

SMC flow meter

CE

10.1-inch-Wide Touch Panel

User Friendly Interface

Multi language