Don’t Miss Your Opportunity to Have Your Tooling Challenges Resolved by Experts at the MACH 2022 Tooling Clinic

/Visitors to MACH 2022 are being offered the unique opportunity to have their tooling challenges resolved free-of-charge by a team of expert – and independent – tooling specialists.

Read more

HMV Catapult Trail returns for MACH 2022

/The strong focus on the future of manufacturing technologies will be highlighted at MACH 2022 by the return of the popular High Value Manufacturing (HVM) Catapult Trail. The HMV Catapult is the go-to place for manufacturing technologies in the UK, supporting organisations of all sizes in their success. The Catapult Trail, consisting of four stands […]

Read more

MACH 2022 to focus on the ability of Additive Manufacturing to ‘rocket boost’ productivity

/The ability of Additive Manufacturing to be a significant disruptive technology for UK manufacturers will receive a special focus at MACH 2022. The focus will be underpinned by the relaunch of the only UK trade association dedicated to the sector, AM-UK. AM-UK is designed for companies who work with Additive and 3D printing technology – […]

Read more

MACH 2022 Education & Development Zone targets next generation engineers

/As with previous MACH exhibitions, MACH 2022 will have a strong focus on encouraging more young people into the engineering and manufacturing technologies industry. Focus of this will the Education & Development Zone, which will feature special displays and a dedicated exhibition zone showcasing the changes taking place within manufacturing and highlighting what makes it […]

Read more

Accelerate investment in UK manufacturing at MACH 2022

/For manufacturers and engineers looking to invest for growth, the arrival of MACH 2022 could not be timelier. The exhibition, which opens its doors at the NEC in Birmingham between 4-8th April, features the largest display of new machinery and manufacturing technologies under one roof in the UK for four years. The Manufacturing Technologies Association […]

Read moreUpgraded laser scanner has improved accuracy, resolution, versatility and efficiency

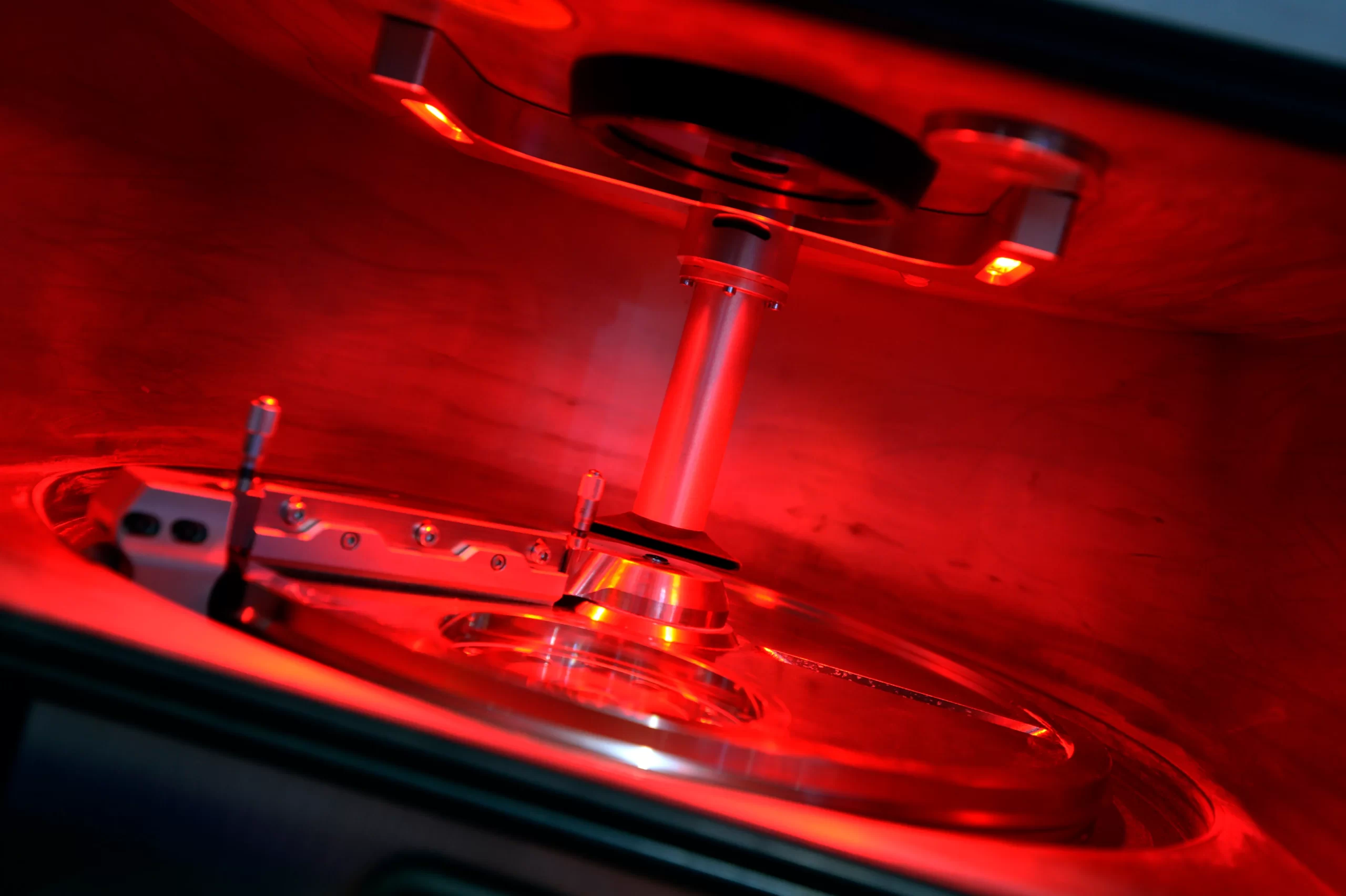

For more than a decade, the LC15Dx laser scanner manufactured by the Industrial Metrology Business Unit of Nikon Corporation (https://industry.nikon.com) has been a global benchmark for efficient measurement and inspection of manufactured components, especially those having complex freeform geometry such as turbine blades, orthopaedic implants and intricate plastic parts. Compatible for use with all industry-leading […]

Read more

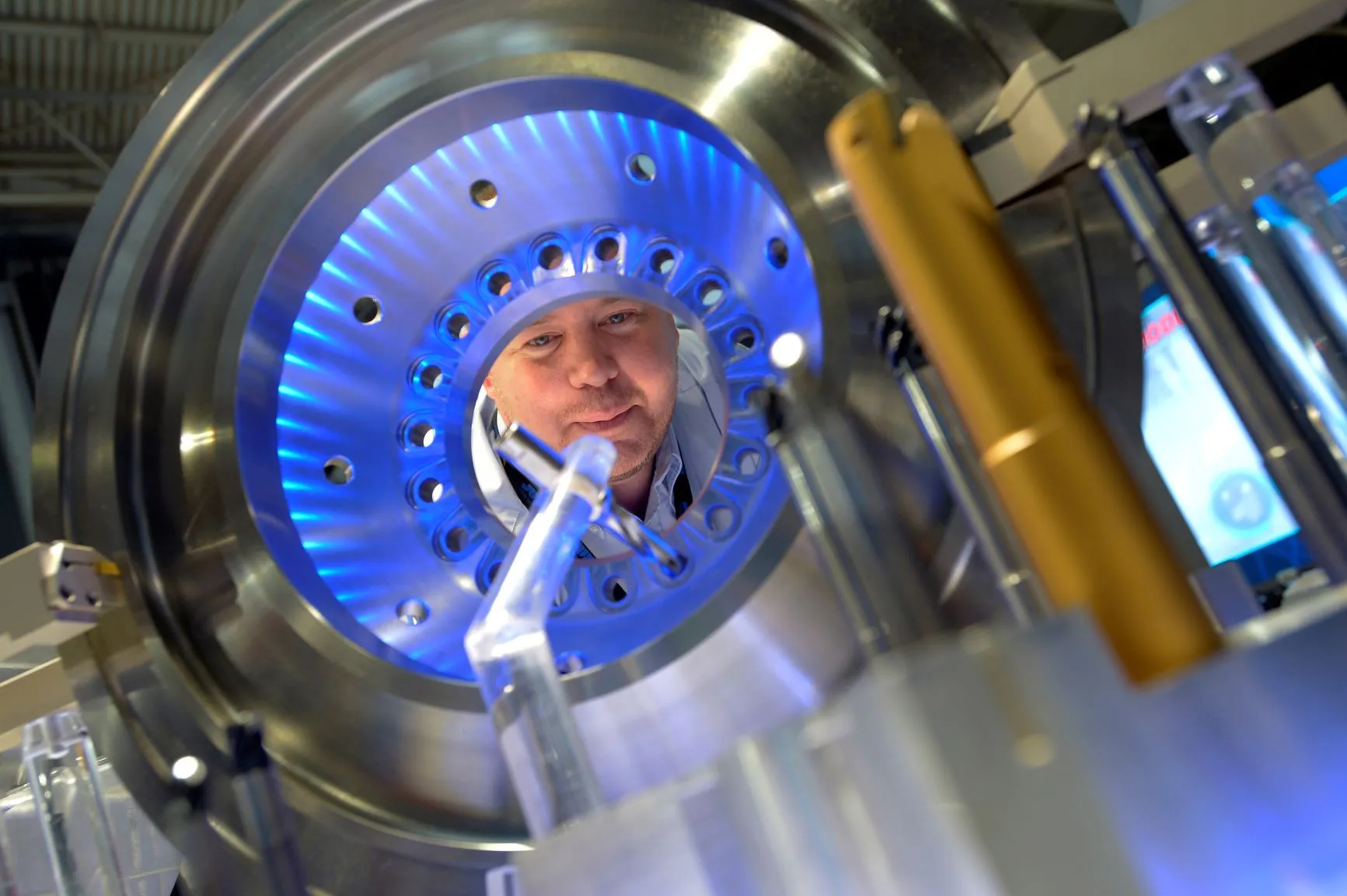

Laser Radar stations from Nikon Industrial Metrology offer powerful new alternative to traditional CMMs

Nikon Industrial Metrology presents an exciting new metrology system for manufacturers seeking to measure the geometry of medium-to-large parts – from a car door, casting or fabrication to a whole car chassis or airframe structure. APDIS Intelligent Quality (IQ) Stations offer a range of Laser Radar solutions as alternatives to traditional, slow, monolithic, inflexible panel […]

Read moreNikon strengthens its X-ray digital inspection solutions by purchasing Avonix Imaging

Nikon Americas Inc, the US subsidiary of Nikon Corporation (Nikon), has purchased the US company Avonix Imaging LLC* (Avonix), Maple Grove, Minnesota, which since 2015 has been a strategic X-ray CT (computed tomography) equipment manufacturing partner to Nikon Industrial Metrology Business Unit (IMBU). As a long-established imaging inspection services provider that uses systems from Nikon […]

Read more

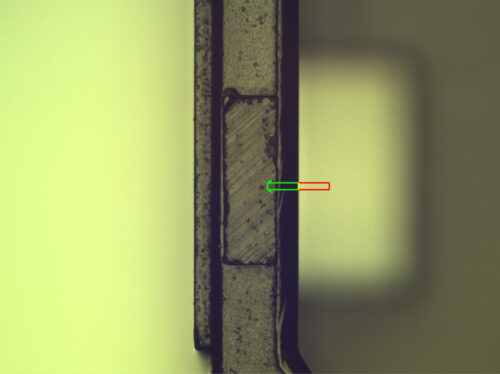

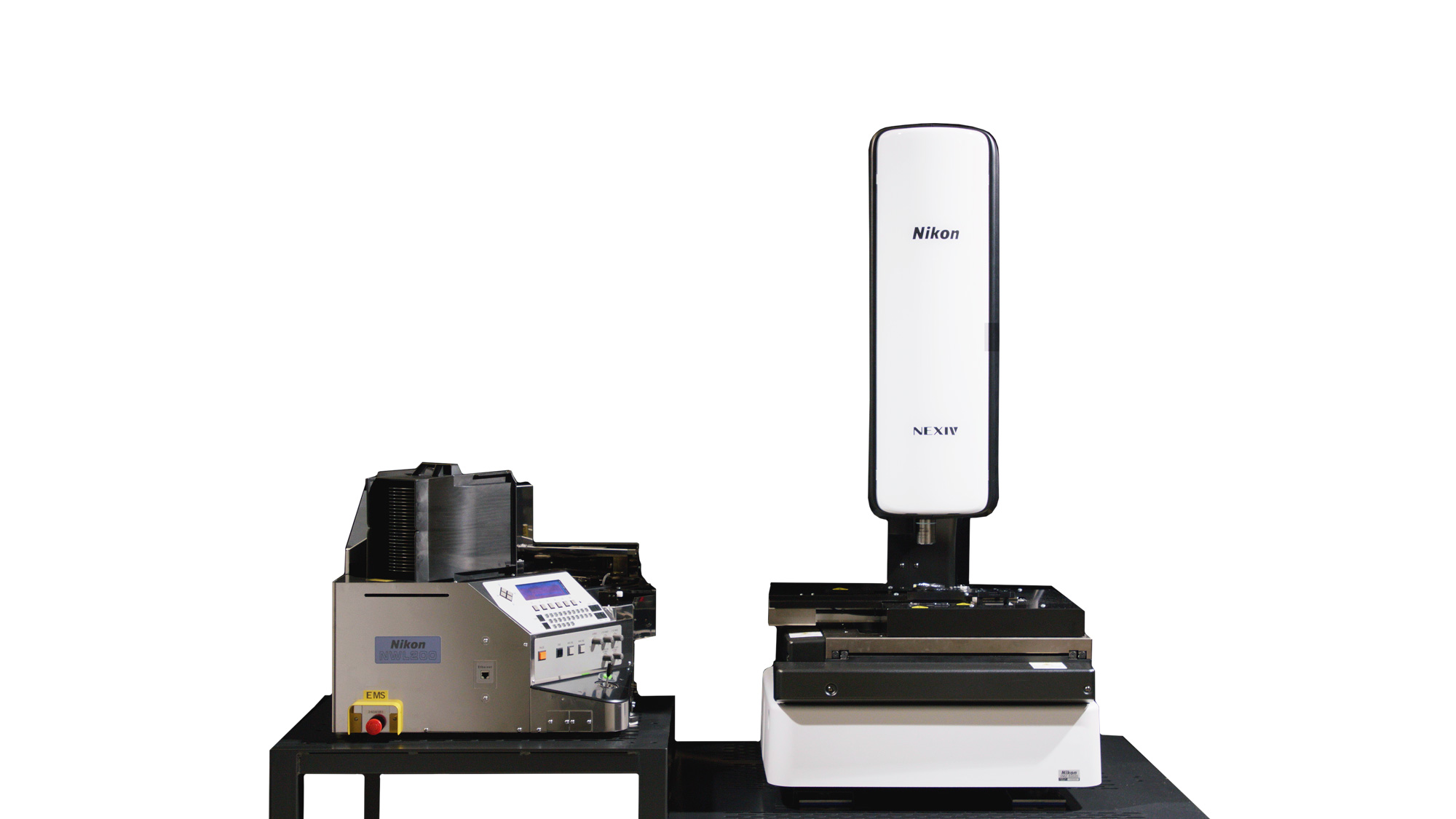

Video measuring software gains automated edge setting function

or more than 30 years, manufacturers using Nikon’s NEXIV series of video measuring machines have harnessed the power of AutoMeasure software, a highly effective platform with which it is easy to create programs for performing precise dimensional measurements. Now the Industrial Metrology Business Unit of Nikon Corporation (https://industry.nikon.com) has announced that the software’s operability has […]

Read more

Wafer automatic measurement solution supports the measurement required for back-end process control

The Industrial Metrology Business Unit of Nikon Corporation has released the automatic wafer measurement system NEXIV VMZ-NWL 200 to solve the challenges of wafer metrology in the semiconductor back-end process, where more work is traditionally carried out manually than in front-end process control. The main target market for NEXIV VMZ-NWL 200 is therefore measurement centered […]

Read more

Tilted CT improves X-ray inspection of components that are flat or contain high density areas

A pioneering X-ray computed laminography (CL) technique has been introduced by the Industrial Metrology Business Unit of Nikon Corporation (https://industry.nikon.com) for non-destructively inspecting challenging components using the computed tomography (CT) systems it manufactures. Called Tilted CT, available now, the new method greatly improves voxel resolution when examining flat, high aspect ratio components. It also enhances […]

Read more

Launch of the Olympus Technologies Universal Robot Press Brake Tending Solution

We are pleased to reveal our Universal Robot press brake tending solution for automating the TRUMPF TruBend family of machines. Our custom designed pneumatic gripper, capable of 180-degree rotation, and individual cup control with feedback, allows for simple and efficient manipulation to give the fastest results with the widest range of parts. The modular gripper […]

Read moreGetting to know about QCT Ltd

QCT have been in business for 31 years, starting as a service company for CMMs (coordinate measuring machine). We initially developed our own CMM operating software, and quickly realised we needed to develop our own CMM hardware interface for manual and CNC CMMs, which allowed us to retrofit or upgrade all makes of CMM. We […]

Read more

Fintek at Mach 2024, Stand 19-16 : 42 Years Of Solving Surface Finishing Problems

42, according to Douglas Adam’s computer creation, Deep Thought, in his acclaimed book Hitchhiker’s Guide to the Galaxy, is the answer to the ultimate question of life, the universe and everything. It doesn’t take Deep Thought to know that a company dedicating 42 years to serving the post processing and surface finishing needs of UK […]

Read more

The new talents of 2023 are here

Start of training in the MAPAL Group At the beginning of September, 57 apprentices started their training in the MAPAL Group and can now look forward to an instructive and interesting time in the company. The junior staff have opted for traditional professions with excellent prospects for the future: 49 of the 57 newcomers will […]

Read more