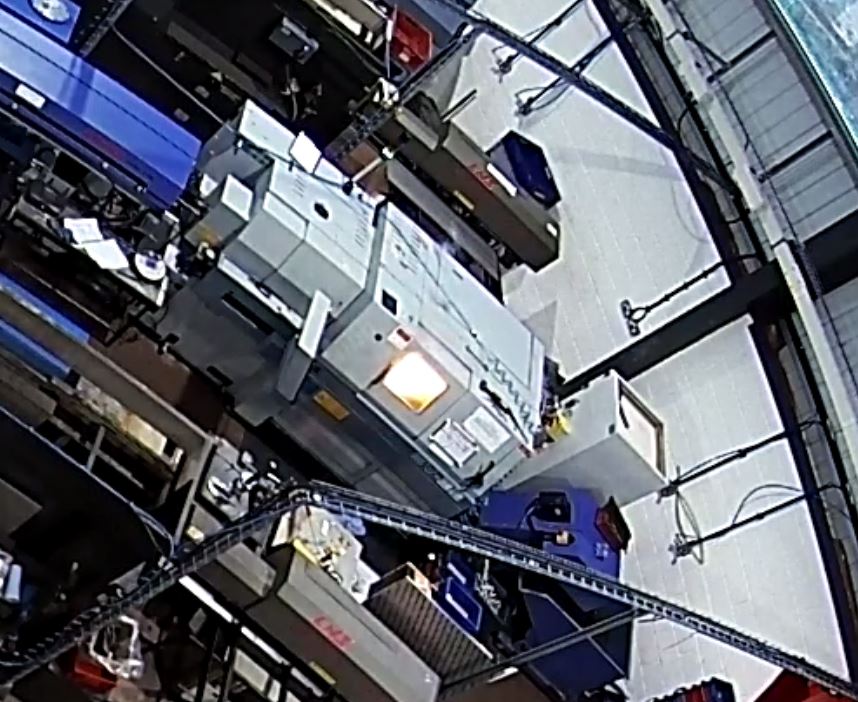

On November 4th 2019, Firetrace Ltd were contacted by a client after their CNC machine caught fire after an unexpected tool failure. Fortunately, they were very relieved and grateful to have had a Firetrace System installed on their machine which suppressed the fire efficiently.

WHY FIRETRACE WERE CONTACTED

Coker Engineering – a precision engineering company based in South West of England for over 35 years experienced a potentional problematic situation when their normal working day and activities became interrupted. This was due to a tool failing in the machine whilst in production and operation. The fire was quickly suppressed with the CO2 Firetrace Automatic Fire Suppression System and the machine shut down with instruction from the Firetrace pressure switch to prevent reignition and any harm. This quick and effective method caused no damage to the machine.

THE SOLUTION AND OUTCOME

From receiving the call regarding the extinguished system, Firetrace Ltd were able to get an engineer to rectify the situation within 48hrs. The system was replaced, and the extinguished system removed from site for safety and disposal purposes.

Giles – Commercial Manager at Coker Engineering stated “Unexpected tool failure caused a flash fire inside one of our sliding head machines whilst it was running high pressure coolant. Thanks to the Firetrace system installed on the machine, the fire was supressed immediately without any damage inside the machine. The machine was back in production 48 hours later, just as soon as Firetrace had been on site to recommission & recharge the system. Disaster averted – worth every penny!”

We are very glad to hear of Coker Engineering positive comments towards our product and are pleased to know that there was minimal disruption and damage to their company. For more information regarding our automatic fire suppression systems and protection your business from fire please contact us 01473744090 or [email protected]