HEIDENHAIN at MACH 2024: solutions for greater process reliability in automated manufacturing

The challenge of automation runs deeper than complex production systems with robots and a pallet pool. It’s also about perfectly tuned workflows that ensure reliable processes. HEIDENHAIN offers effective solutions.

This year at MACH, HEIDENHAIN is showcasing the TD 110 tool breakage detector for in-process tool inspection. This includes a live demo in conjunction with the StateMonitor machine data collection software.

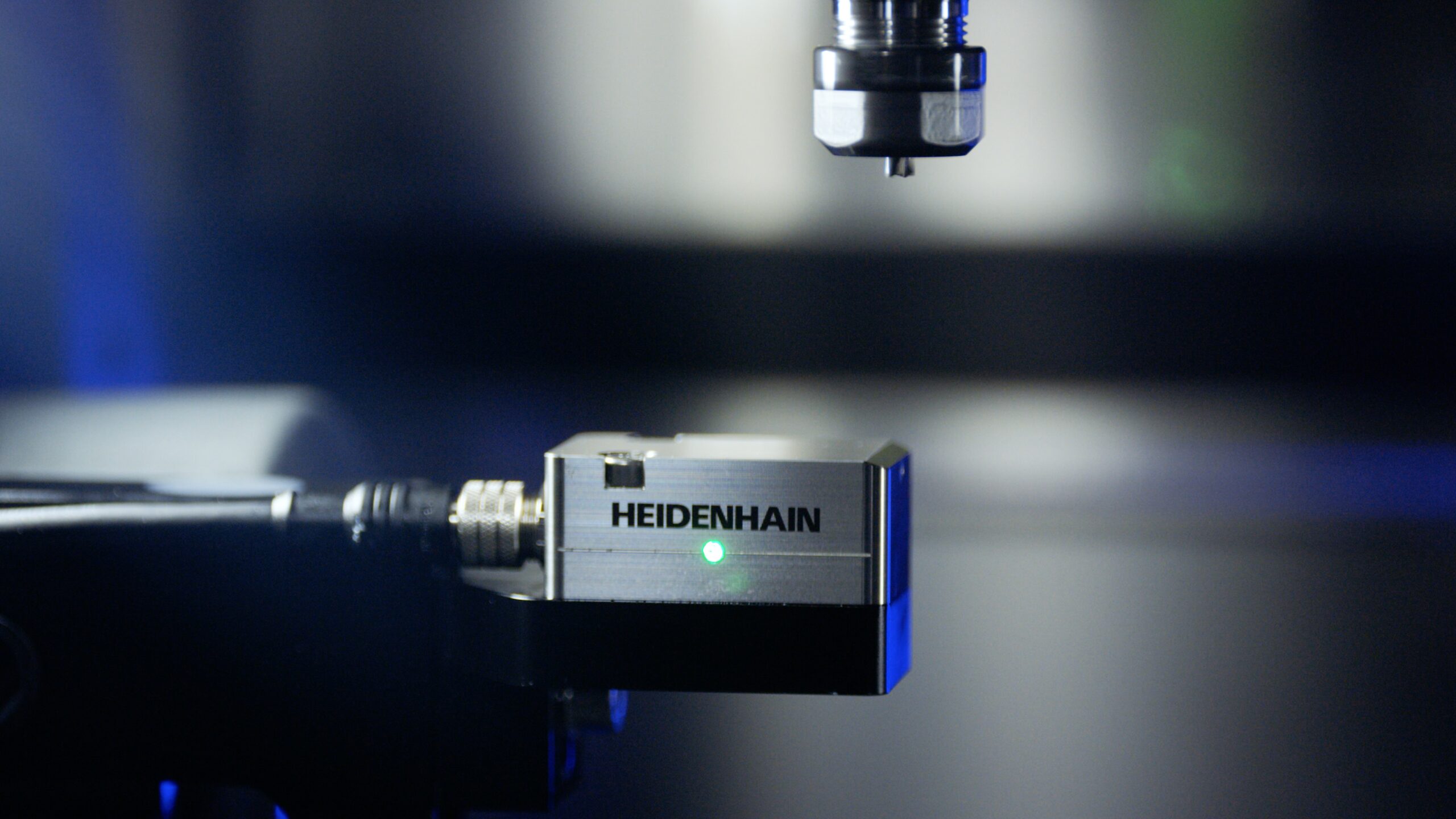

The TD 110 tool breakage detector from HEIDENHAIN: convenient in-process tool inspection

Automatically detect broken tools in automated processes and prevent damage during subsequent machining operations. The TD 110 increases process reliability without interrupting machining by detecting broken tools passing by on their way to or from the tool magazine, thereby preventing them from being used in the first place. This compact and robust sensor can be added to the workspace of any machine tool in close proximity to the machining table. Its signals are sent to the control via the touch-probe interface. The control then triggers a machine message, NC stop or a reaction defined by the user, such as a message to StateMonitor.

The TD 110 tool breakage detector inspects tools with a diameter of at least 0.4 mm and performs non-contact breakage detection starting with a length change of 2 mm. This happens inside the machine envelope with the spindle rotating at its operating speed. This considerably increases the process reliability and shaves up to six seconds off of every inspection compared with conventional laser systems. The time and cost benefits during tool changes are considerable. And because the TD 110 operates without compressed air, its carbon footprint is small. Installation is also easy thanks to the omission of air hoses and filter systems. All that’s needed instead is a single cable carrying both power and communication. And thanks to its inductive measurement technology, the TD 110 is maintenance-free.

Live demo at MACH: “The TD 110, TNC7 and StateMonitor software from HEIDENHAIN”

The live product demonstrations on the machine at the HEIDENHAIN trade-show booth include a demonstration of the TD 110 using the breakage inspection cycle of the TNC7, including an alert to the StateMonitor software from the HEIDENHAIN Digital Shop Floor. The breakage inspection cycle for HEIDENHAIN controls evaluates the inspection as follows:

• Tool intact = The production process can be continued, and a notification is sent to the control and to StateMonitor.

• Tool breakage detected = The user is free to define the desired action, such as locking the tool, interrupting the NC program, notifying the control and alerting StateMonitor. The TD 110 is also connected to StateMonitor as a signal message.

This allows relevant staff members to be informed of the breakage. Thanks to the StateMonitor messenger function, this accelerates reaction times, such as during simultaneous multi-machine operation. Connecting the sensor to StateMonitor also enables a detailed analysis of breakages over time.